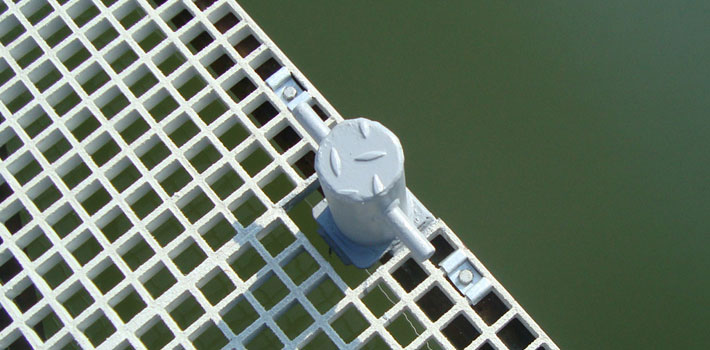

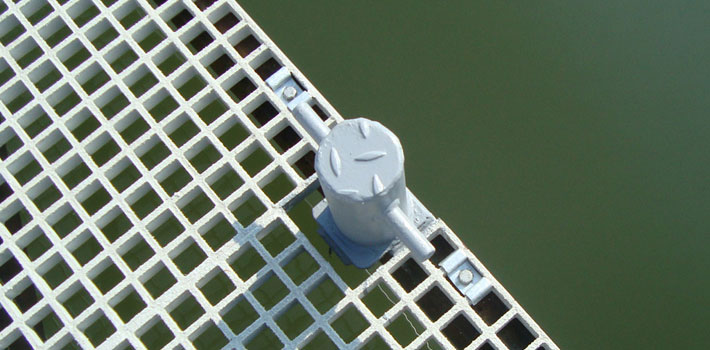

A Fibreglass Reinforced Plastic grating moulded has multiple applications in industrial, corrosive and chemically hazardous environments.

Moulded Fibreglass Reinforced Plastic grating (cast)

This type of Fibreglass Reinforced Plastic grating is cast in a mould (moulded). It is a composite material consisting of layered fiberglass overcast with a polyester or vinylester resin (65%). The specific production process ensures that this type of Fiberglass Reinforced Plastic grating has optimal strength in two directions. Furthermore, this FRP grating has excellent corrosion resistance. The performance of moulded Fibreglass Reinforced Plastic (FRP) grating is excellent and reliable, even in the most demanding and corrosive conditions. The unique properties ensure it has excellent corrosion resistance in a wide pH range of both acid and corrosive substances.

Available grating thickness (grating thickness)

FRP grating (moulded) is available in the grating thicknesses: 13, 25, 30, 38 and 50 millimetres. The FRP (GRP) grating panels are available in various lengths and sizes.

FRP (GRP) grating, high-strength, safe and very versatile!

The (moulded) FRP grating is high-strength, safe (non-slip), low-maintenance and very versatile in use. This type of FRP (GRP) grating is often used for landings, floors, walkways, stair cases and platforms. FRP grating is highly corrosion-resistant and therefore extremely suitable for use in the most chemically hazardous environments. For example:

- sewage treatment plants

- the petrochemical industry

- civil engineering / rail infrastructure

- power stations

- the chemical industry

- process-water and drinking-water companies

- the food, drink and tobacco industry

- waste processing companies

- incineration plants

- shipping and offshore industry

- agricultural sector

- marinas

The advantages of FRP (GRP) grating

Use of FRP grating contributes significantly to safety, corrosion resistance, durability and low maintenance control of e.g. platforms and installations. Furthermore, FRP grating is also an excellent alternative to steel, wooden and concrete grating.

- strong in two directions

- low-maintenance (Does not rust, does not rot)

- safe: good non-slip properties

- corrosion-resistant

- non-sparking

- non-conducting

- lightweight

- easy to process

- easy to install

Fibreglass Reinforced Plastic grating applications

Fiber Reinforced Plastic grating is very versatile in application, e.g. floors, walkways, staircases, landings, platforms, drainage gutters, cable ducts, production and storage spaces, mezzanines, (water) discharge channels, etc.

Cast Fibreglass Reinforced Plastic (FRP) grating is recommended when corrosion and safety are important issues. We can advise you on the type of grating, a grating installation plan and customisation, entirely without obligation.

Do you want to know more about FRP grating?

Please call FlexxCon: +31334556696 or send an e-mail.