Pultruded grating is suitable for applications with a large span and a high load. Pultruded grating is highly fire-resistant and can be used in various heavy industrial environments and chemical, aggressive and corrosive conditions.

Pultruded Fibreglass Reinforced Plastic grating

Pultruded FRP grating is made of fibreglass reinforced plastic (FRP [GRP]). Pultruded FRP (GRP) grating consists of pultruded load bars that are interconnected by means of tie bars. This grating can be supplied in a polyester, vinylester or phenolic resin. Phenolic resin has excellent properties with respect to fire resistance.

Large spans, high loads

Due to the specific construction and the use of a high glass percentage (approximately 65-70%), pultruded Fibreglass Reinforced Plastic (FRP) pultruded grating is high in strength. Pultruded Fibreglass Reinforced Plastic grating is therefore widely applied in applications that require high strength and at a large span (from 1 to 2 metres).

FlexxCon supplies pultruded FRP grating in various panel sizes and thicknesses, with variations in tie rod distance and open spaces. Fibreglass reinforced plastic (FRP [GRP]) pultruded grating can be fitted with a quartz surface (anti-slip layer) and a solid cover plate.

Available grating thicknesses

Fibreglass Reinforced Plastic grating (pultruded) is available in the thicknesses: 25 and 38 millimetres. The Fibreglass Reinforced Plastic grating panels are available in various sizes.

Pultruded castwalks, high strength and fire resistant

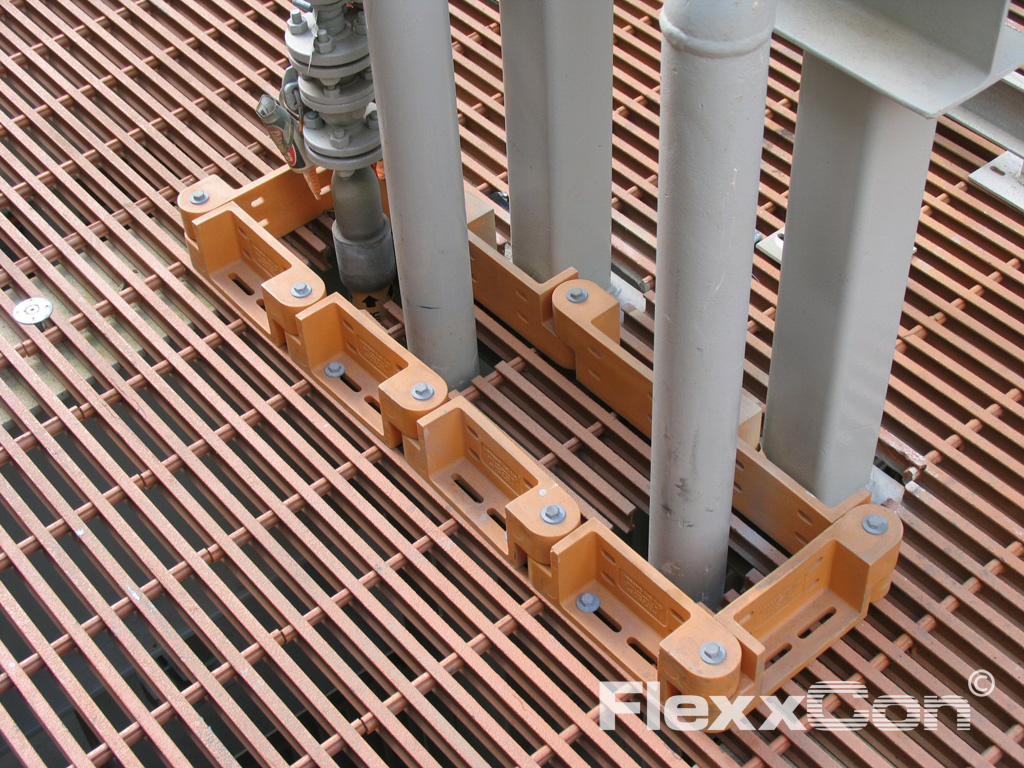

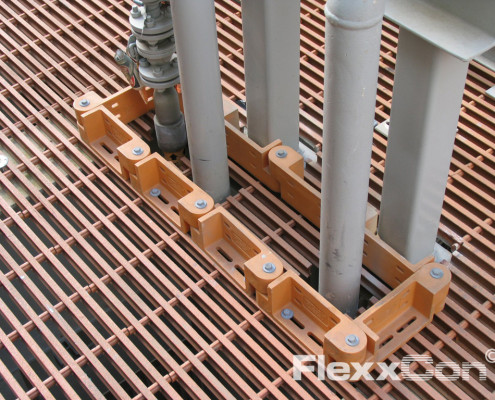

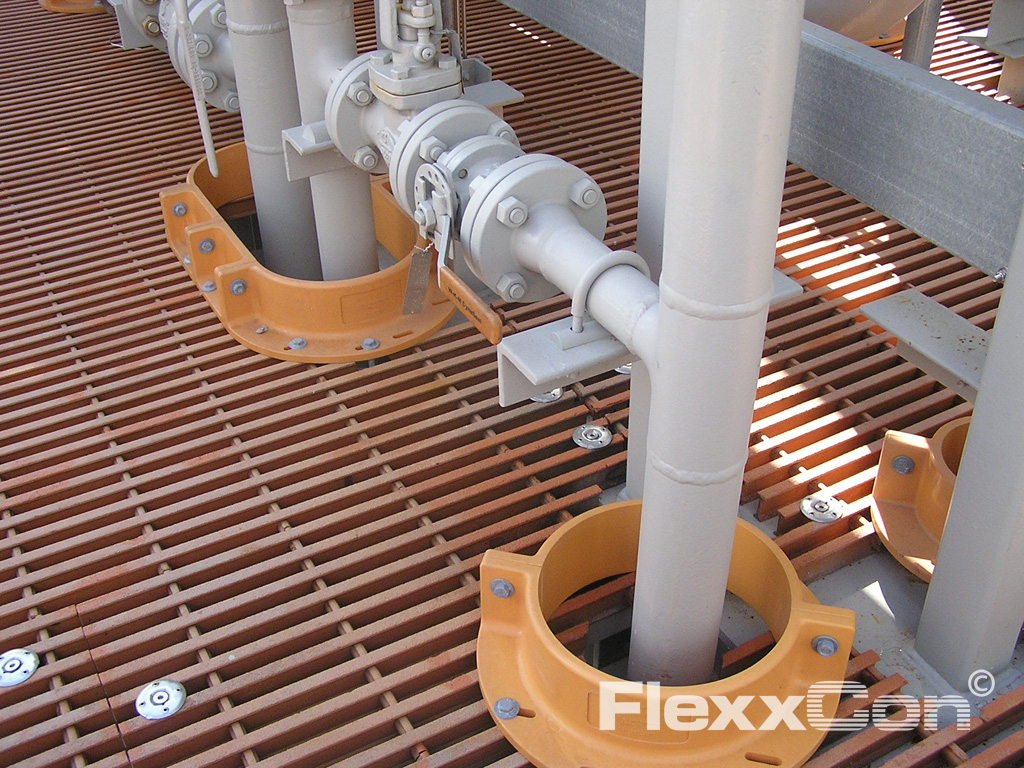

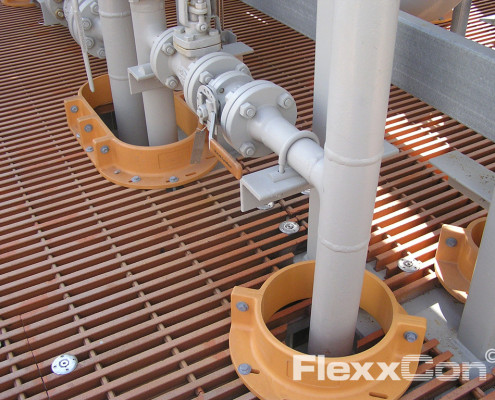

The (pultruded) FRP grating is high strength, fire resistant, safe (anti-slip layer), low-maintenance and very versatile in use. This type of Fiber Reinforced Plastic (GRP) grating is often used for floors, walkways, staircases and landings, and platforms.

FRP grating has excellent corrosion resistance and is therefore extremely suitable for use in the most chemically hazardous of environments, such as:

- the heavy (petro) chemical industry

- shipping and offshore

- sewage treatment plants

- waste-processing companies

- incineration plants

- civil engineering and rail-infrastructure

- power stations

- drinking water companies

- the food, drink and tobacco industry

The advantages of Fibre glass Reinforced Plastic (FRP) grating

Fiber Reinforced Plastic grating makes a considerable contribution to safety, corrosion resistance, durability, and maintenance-free control of platforms and industrial installations. Fibre glass Reinforced Plastic grating is also a good alternative for steel (stainless steel), wood and concrete grating.

- high strength

- low-maintenance

- safe surface: anti-slip layer

- corrosion resistant

- non-conducting

- non-sparking

- lightweight

- easy to process

- easy to install

FRP grating applications

FRP grating is very versatile in application and can be used in: floors, walkways, staircases, landings, platforms, drainage gutters, cable ducts, production and storage spaces, mezzanines, (water) discharge channels, etc.

FlexxCon, specialist in FRP grating

We are happy to advise you on the type of FRP grating, applications, installation plan and customisation.

More information? Call FlexxCon: +31334556696 or send an e-mail.